In our interrelated world, the modern supply chain is the support that keeps goods and services elegant. Whether you’re procuring a new laptop or stocking up on foodstuffs. That product has experienced an extensive journey linking multiple procedures and parties.

Accepting how the supply chain management process works is essential for businesses struggling to meet client demands proficiently while controlling costs and continuing a reasonable edge.

What Exactly Is Supply Chain Management?

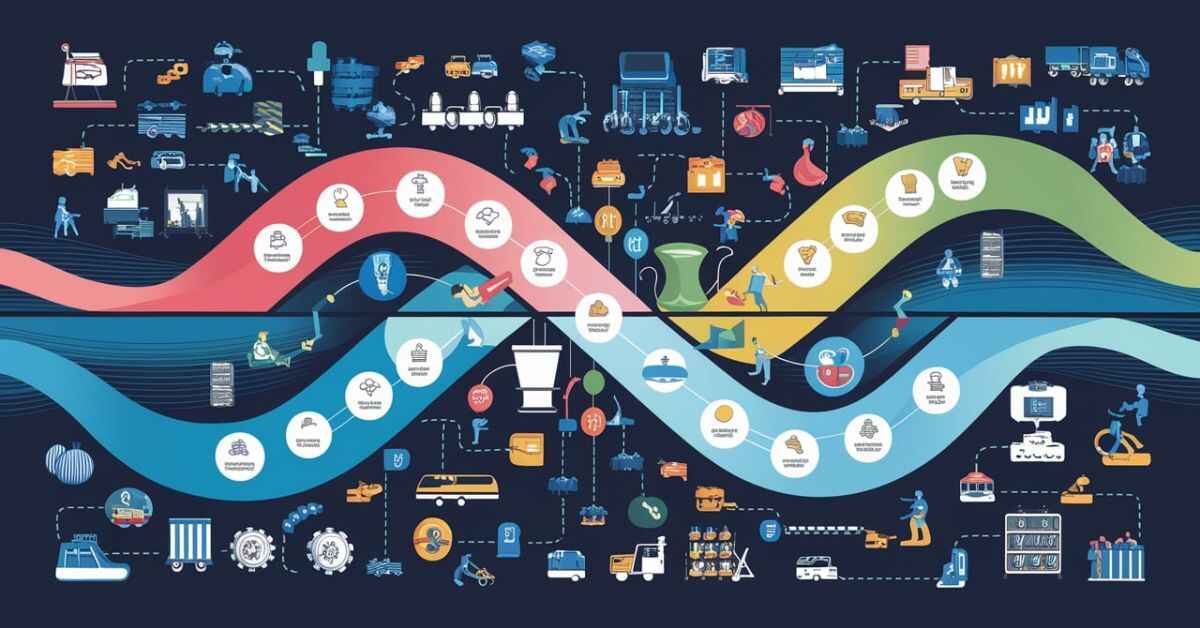

Supply chain management (SCM) discusses to the incorporated end-to-end procedures involved in planning sourcing manufacturing and supplying products or services to the end consumer. It incorporates all the interrelated activities and logistics necessary to change raw supplies into completed goods and ensure their accessibility to consumers.

- Planning and Strategy: Forecasting demand allocating resources and developing a strategic plan to align supply with customer needs.

- Sourcing and Procurement: Identifying and selecting reliable suppliers negotiating contracts and acquiring the necessary materials or components.

- Manufacturing Operations: Overseeing production processes quality control assembly of goods.

- Logistics and Distribution: Managing the storage and transportation delivery of finished products to customers or retailers.

- Customer Service and Returns: Facilitating order fulfillment handling customer inquiries and managing the reverse logistics of returned or defective items.

To illustrate the concept, conceive you’re buying a new smartphone. The supply chain procedure begins with the development and forecasting of demand for that detailed model. The required modules (like processor screen cases) are sourced from numerous suppliers through planned procurement processes. These machineries are then assembled in a manufacturing facility undergoing difficult quality checks.

The complete smartphones are stored in warehouses before being dispersed through various transportation modes (air, sea, or ground) to vendors or directly to clients. Finally, if any issues arise a rear logistics system grips returns or looks after them.

Read this Blog: Accelerate Your Career: Top Supply Chain and Operations Management Jobs with SCM Degrees

The End-to-End Supply Chain Process Flow

Now that we have a basic consideration of supply chain management, let’s delve unfathomable into the step-by-step process flow:

Planning & Strategy

Effective supply chain management begins with comprehensive planning and strategy development. This stage involves:

- Demand Forecasting: Analyzing historical data market trends and consumer behavior to predict future demand for products or services accurately.

- Resource Allocation: Assessing and allocating the necessary resources such as raw materials, manufacturing capacity workforce, and logistics infrastructure to meet the forecasted demand.

- Strategic Planning: Developing a holistic supply chain strategy that aligns with the organization’s overall business objectives considering factors like cost optimization, risk mitigation, and sustainability.

A prime example of real planning is Apple’s supply chain policy. The tech giant accurately forecasts global demand for its products securing long-term supplier contracts and carefully handling inventory levels to meet consumer prospects while diminishing excess stock.

Sourcing & Procurement

Once the development phase is complete, the next step is obtaining the required materials and components services from reliable suppliers. This stage involves:

- Supplier Selection: Identifying and evaluating potential suppliers based on criteria such as quality, cost, delivery times, and reliability.

- Contract Negotiation: Negotiating favorable terms and conditions, including pricing, payment terms, and service-level agreements (SLAs) with selected suppliers.

- Purchase Order Management: Generating and tracking purchase orders, ensuring timely delivery of materials or components.

It’s crucial to consider probable contests that may arise, such as supply shortages geopolitical issues, or supplier non-compliance. To alleviate these risks corporations often implement policies like multi-sourcing retaining safety stock levels developing eventuality plans.

One helpful tip for obtaining quality things is to deportment thorough supplier audits assessing their production facilities’ quality control processes’ compliance with industry standards or guidelines.

Manufacturing Operations

With the essential materials and machinery secured, the next stage is manufacturing operations where the real production and get-together of goods take place. This stage involves:

- Production Scheduling: Coordinating and scheduling manufacturing activities, machinery, and personnel to optimize efficiency and meet delivery timelines.

- Quality Control: Implementing rigorous quality assurance processes, such as inspections, testing, and adherence to industry standards, to ensure product quality and safety.

- Assembly and Packaging: Assembling components into finished goods, followed by packaging and labeling for distribution.

A prime example of lean manufacturing success is Toyota’s renowned Toyota Production System (TPS). By eliminating waste, establishing continuous workflow, and empowering workers, Toyota has achieved exceptional efficiency and quality in its manufacturing operations.

Logistics & Distribution

Once the harvests are manufactured, the next serious step is logistics and delivery ensuring the smooth flow of goods from the production facility to the end customer. This stage involves:

- Warehouse Management: Overseeing the storage inventory management and organization of finished goods in warehouses or distribution centers.

- Transportation and Shipping: Coordinating the efficient movement of products through various transportation modes. Such as air-sea rail ground based on factors like cost speed and destination.

- Order Fulfillment: Processing and fulfilling customer orders including activities like picking packing shipment tracking.

To illustrate the reputation of logistics, consider the hominid body’s circulatory system, which carriages oxygen and nutrients to vibrant organs. An efficient logistics system acts as the circulatory system for the supply chain ensuring the timely delivery of things to the right last stop.

Customer Service & Returns

The final stage of the supply chain management process rotates around customer service and proceeds management. This stage encompasses:

- Order Tracking and Support: Providing customers with real-time order status updates and handling inquiries or issues promptly.

- Reverse Logistics: Managing the return and processing of defective, damaged, or unwanted products, including repair, refurbishment, or disposal.

- Customer Feedback and Improvement: Collecting and analyzing customer feedback to identify areas for improvement and enhance the overall customer experience.

According to a survey by PwC, 73% of consumers cited exceptional customer service as a key factor in their purchasing decisions. This statistic highlights the importance of prioritizing customer service and efficient returns processing within the supply chain management process.

Optimizing the Supply Chain

While the core supply chain management processes remain consistent, optimizing and continuously improving these processes is crucial for maintaining a competitive edge. Strategies for supply chain optimization include:

- Lean and Six Sigma Methodologies: Implementing lean principles to eliminate waste and non-value-added activities, and leveraging Six Sigma techniques to enhance process efficiency and reduce defects.

- Technology Adoption: Leveraging cutting-edge technologies like artificial intelligence (AI), machine learning, the Internet of Things (IoT), and advanced analytics to gain real-time visibility, automate processes, and drive data-driven decision-making.

- Collaboration and Integration: Fostering seamless collaboration and data sharing among all supply chain partners, enabling end-to-end visibility and better coordination.

- Sustainability Initiatives: Incorporating sustainable practices, such as eco-friendly packaging, renewable energy sources, and responsible sourcing, to reduce the environmental impact of supply chain operations.

Benefits of an Optimized Supply Chain

By continuously optimizing the supply chain management process, organizations can reap numerous benefits, including:

- Cost Savings: Streamlined processes, reduced waste, and improved efficiency lead to lower operational costs and increased profitability.

- Faster Cycle Times: Optimized workflows and real-time visibility enable quicker response times, shorter lead times, and faster delivery to customers.

- Improved Customer Satisfaction: Enhanced order accuracy, on-time deliveries, and efficient returns handling contribute to better customer experiences and loyalty.

- Increased Agility and Resilience: A well-optimized supply chain can adapt more quickly to market changes, disruptions, or unexpected events, mitigating risks and ensuring business continuity.

- Competitive Advantage: By optimizing their supply chain processes, companies can gain a competitive edge over rivals, leading to increased market share and revenue growth.

To track the effectiveness of supply chain optimization efforts, organizations typically monitor key performance indicators (KPIs) such as:

- Inventory Turnover Rate: Measures the efficiency of inventory management and avoids excessive stock levels.

- On-Time Delivery Rate: Tracks the percentage of orders delivered to customers within the promised timeframe.

- Perfect Order Rate: Evaluates the percentage of orders delivered complete, on-time, and without any errors or damage.

- Supply Chain Costs as a Percentage of Revenue: Monitors the overall supply chain costs relative to the organization’s revenue, highlighting areas for cost optimization.

By continuously analyzing and optimizing these performance metrics organizations can identify bottlenecks inefficiencies and areas for improvement within their supply chain management processes.

Conclusion

The supply chain management process is a complex, multi-faceted endeavor that underpins the smooth flow of goods and services from suppliers to end customers. By breaking down and understanding each step from planning and sourcing to manufacturing logistics and customer service businesses can streamline their operations enhance efficiency and deliver superior value to consumers.

As we’ve explored effective supply chain management involves meticulous planning, strategic sourcing lean manufacturing efficient logistics and exceptional customer service. However the true key to success lies in continuously optimizing these processes through strategies like lean methodologies technology adoption cross-functional collaboration, and sustainability initiatives.

![Find a Section 8 houses for rent with no deposit Revealed! [2024]](https://busslirra.com/wp-content/uploads/2024/08/Find-a-Section-8-houses-for-rent-with-no-deposit-Revealed-2024-300x157.jpg)

![Find a Section 8 houses for rent with no deposit Revealed! [2024]](https://busslirra.com/wp-content/uploads/2024/08/Find-a-Section-8-houses-for-rent-with-no-deposit-Revealed-2024-150x150.jpg)